Spis treści:

BDHM…A DEHUMIDIFIERS

Dehumidifying capacity: 10– 29 kg/h*

Dry air efficiency: 1500 – 5000 m3/h

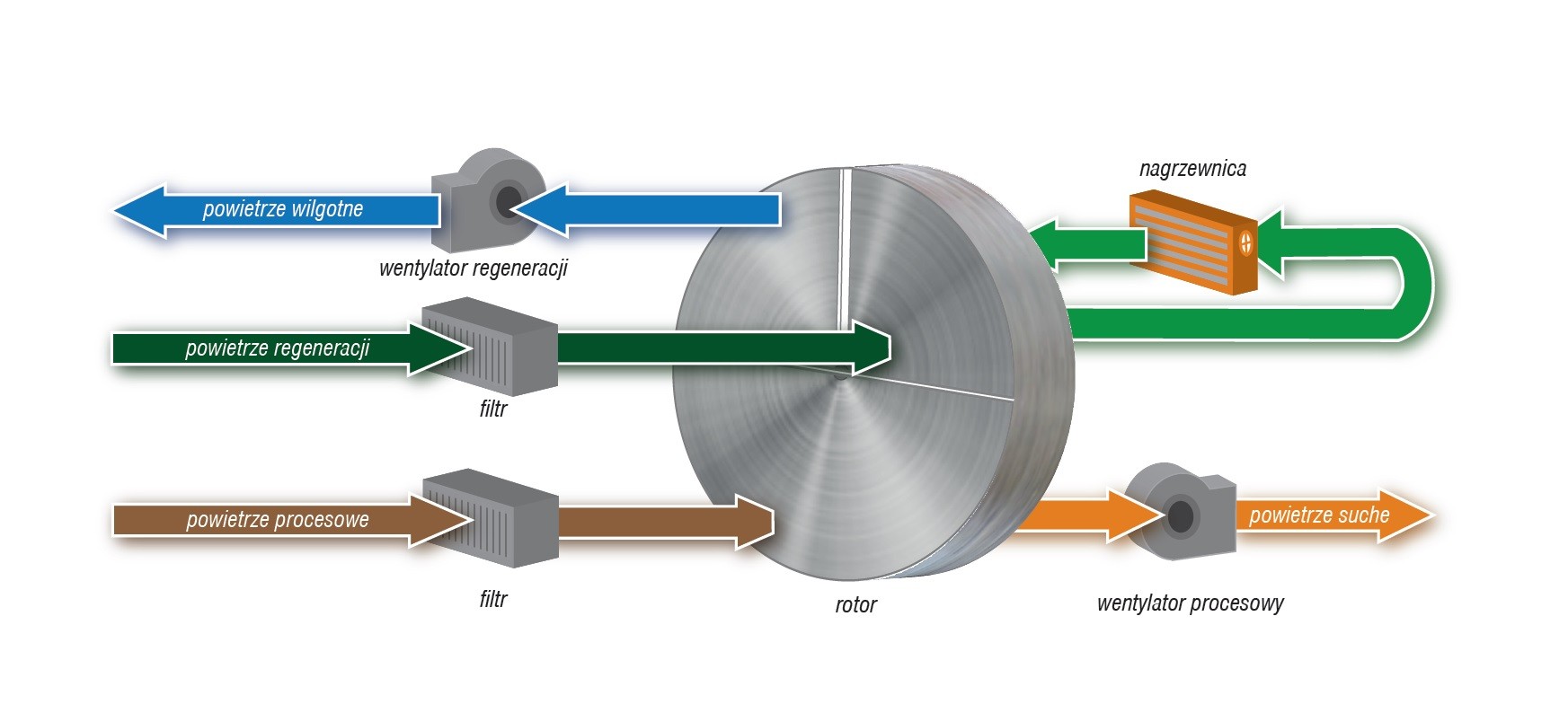

Compact, adsorption dehumidifiers DHM…A connect high efficiency, solid design and placing all required elements with possibly the smallest body. Similar to all adsorption dehumidifiers, they are built basing on an adsorption rotor made of carbon soaked in silica gel. Thanks to this, maximal dehumidification effect can be achieved.

Compact dehumidifiers are dedicated to applications where the key factor is space use, and there is no need to equip the device in additional elements, i.e. air cooler or additional filters.

+48 56 46 811 77

+48 56 46 811 77 biuro@lewaco.pl

biuro@lewaco.pl