Spis treści:

BDHM…R DEHUMIDIFIERS WITH HEAT RECOVERY

(efficiency 4.6 to 96 kg/h*)

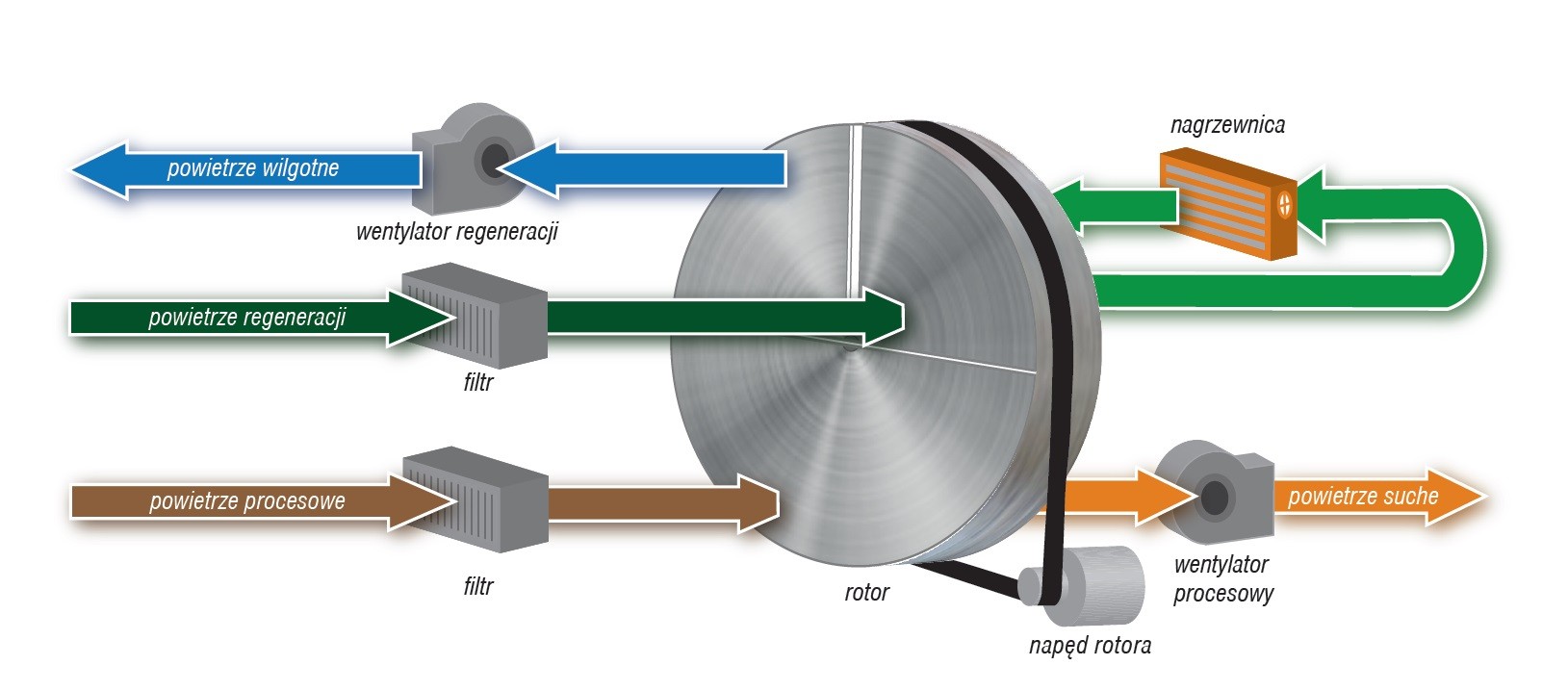

BDHM…R adsorption dehumidifiers were designed to recover heat internally with the nominal dehumidification efficiency, and at the same time limit power consumption. Similar to all adsorption dehumidifiers, they are built basing on an adsorption rotor made of carbon soaked in silica gel. Thanks to this, maximal dehumidification effect can be achieved.

Models with efficiency up to 10 kg/h* are made of stainless steel. Bigger devices have bodies made of aluminium and insulated panels

Additional advantage of devices from this series is the option to adjust the device to recommendations and requirements of the customer by creating special versions (it is possible to equip the dehumidifier with new elements and modify parameters, i.e. amount of dry air, fan compressions etc.) Thanks to this, the dehumidifier extends its functions with additional filtration or regulation of air temperature.

Dehumidifiers have PZH certificates which allow to use them in food and pharmaceutical industries.

+48 56 46 811 77

+48 56 46 811 77 biuro@lewaco.pl

biuro@lewaco.pl