Spis treści:

DHM…D DEHUMIDIFIERS – two separate fans

Dehumidifying capacity: 0.6– 4.2 kg/h*

Dry air efficiency: 190 – 700 m 3 /h

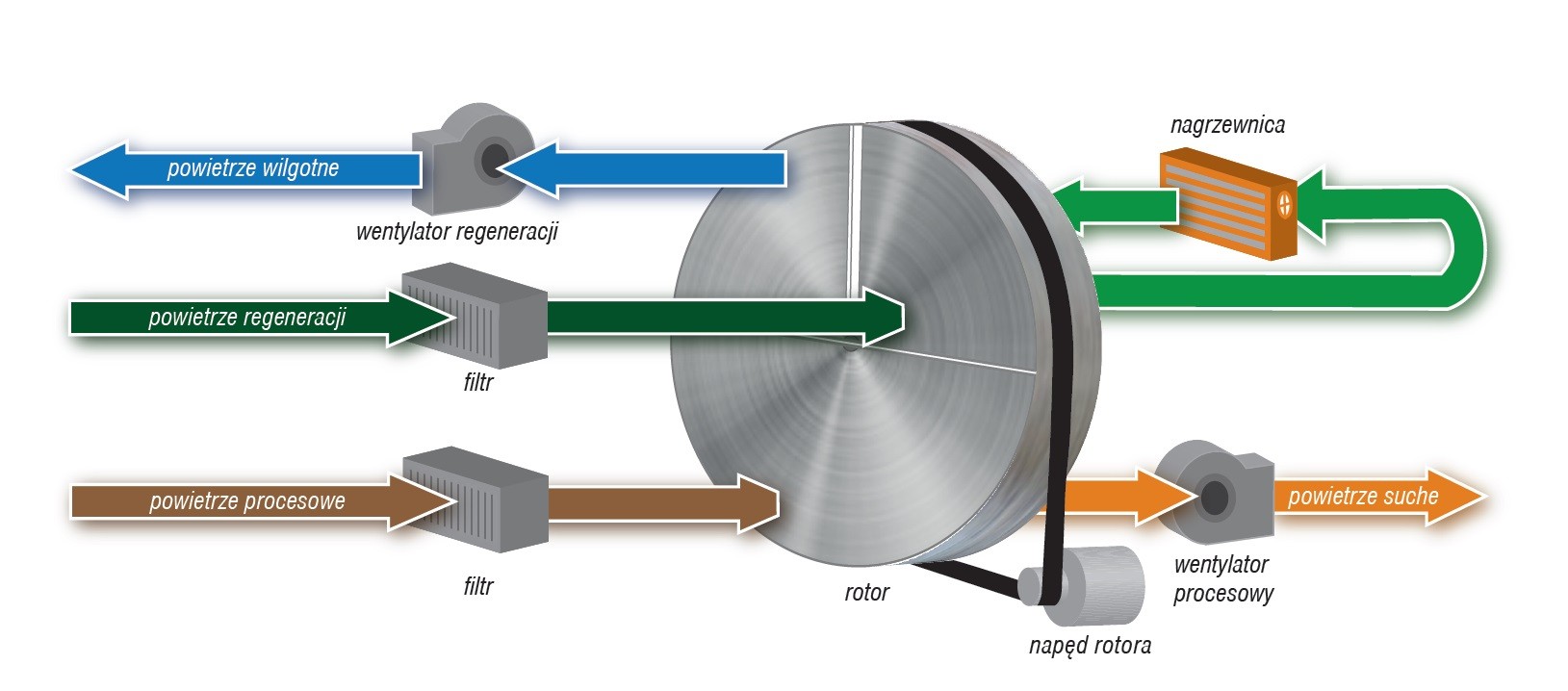

Compact, adsorption dehumidifiers DHM combine high efficiency, solid design and small dimensions. Similar to all adsorption dehumidifiers, they are built basing on an adsorption rotor made of carbon soaked in silica gel. Thanks to this, maximal dehumidification effect can be achieved. All DHM devices have bodies made of stainless steel. DHM…D adsorption air dehumidifier with an electronic regeneration heater and two fans can be used in closed systems, where the dehumidifier does not select fresh air, and where both temperature and humidity are tightly under control.

Advantages:

- stainless steel body

- dust-free, washable, durable drying rotor

- small weight, handles enabling moving

- adjusted to connection of round ventilation dust ducts and elastic wires

- high dehumidification efficiency

- G4 class process filters

- they can be used in construction industry, storage space dehumidification, water treatment plants, military objects, production halls

- dehumidifiers can work in the full humidity range (0-100%RH) and below zero temperatures (-25C to +40C)

+48 56 46 811 77

+48 56 46 811 77 biuro@lewaco.pl

biuro@lewaco.pl